Why are hydrogen compressors important for refuelling?

by Admin

Posted on 13-05-2024 01:30 PM

For more than 20 years, sundyne’s compressors and pumps have played an important role in the production, transportation and distribution of hydrogen around the globe. Sundyne’s ppi compressors are specifically designed to address the challenges associated with compressing h2 from low pressure levels (such as electrolyser outlet pressure) up to the 350 or 700 bar levels that are required by today’s vehicles that run on hydrogen. The centrifugal integrally-geared compressors in the lmc/bmc/lf-2000 series are engineered to optimize the efficiency of hydrogen compression for energy, petrochemical, chemical and industrial businesses.

Available from 100 to 17,000 m3/hr, these compressors are a preferred choice for h2 gas applications.

Available from 100 to 17,000 m3/hr, these compressors are a preferred choice for h2 gas applications.

The quality of hydrogen fuel, used in hydrogen powered cars, trucks, buses and other hydrogen fuel cell vehicles, is critical for proper operation of the fuel cells. Contaminants originating in the hydrogen supply can damage fuel cells, therefore it is critical that purity is effectively managed during the hydrogen refuelling processes to reduce the risk. Haskel’s full range of hydrogen compressors are designed specifically to prevent any cross contamination of the gas to ensure that gas purity is maintained throughout the refuelling process. Read more in our blog - maintaining hydrogen gas purity for hydrogen refuelling using a hydraulic compressor | haskel.

Our hydrogen compressors are equipped with several important safety features to ensure the safe handling and operation of compressed hydrogen. Safety interlocks are implemented to prevent operation unless specific safety conditions are met, adding an extra layer of protection. The compressors also incorporate advanced leak detection systems that continuously monitor for any hydrogen leaks within the compressor or associated piping. In the event of a leak, alarms are triggered, and appropriate actions can be taken to mitigate the situation. Additionally, our compressors are equipped with emergency shutdown capabilities, allowing for immediate and safe shutdown in the event of a safety breach or abnormal operating conditions.

How do Haskel hydrogen compressors maintain gas purity?

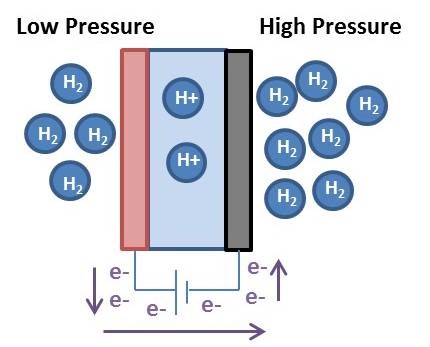

Haskel hydraulic compression skids for hydrogen filling are fully integrated hydrogen transfer systems that take hydrogen gas from low to high pressure using the manufacturer’s proven hydraulic h-drive compression technology. Configured to your filling requirements, the compact, transportable compression skid can be used as part of a larger hydrogen refueling solution or a cost-effective direct filling system. Haskel hydraulic compression skids are engineered to customer specifications and can be designed to meet specific filling requirements for a range of applications. Features & benefits

delivers up to 1,000 kg/day at pressures up to 100 mpa. Flexible hydrogen supply.

Compressor designed to maintain hydrogen gas purity.

Compressor designed to maintain hydrogen gas purity.

Are Haskel compressors suitable for hydrogen applications?

Oil-based lubricated compressors cost less, provide a longer service life compared to oil-free compressors, and are considered ideal for commercial and industrial applications until and unless in industries where consequences of oil contamination are considered very high and having an oil-free compressor is a must. Oil-based compressors are considered more efficient than the oil-free type compressors, as oil acts as a cooling medium, taking out approximately 80% of the compressor's heat during the compression process, and considered more suitable for industrial usage with requirements of a high compression ratio. In terms of capital outlay, lubricated oil-based compressors are often considered less expensive than oil-free compressors, with price differences often varying in the range of 30-40%.

Several methods exist for storing hydrogen. These include mechanical approaches such as using high pressures and low temperatures, or employing chemical compounds that release h2 upon demand. While large amounts of hydrogen are produced by various industries, it is mostly consumed at the site of production, notably for the synthesis of ammonia. For many years hydrogen has been stored as compressed gas or cryogenic liquid, and transported as such in cylinders, tubes, and cryogenic tanks for use in industry or as propellant in space programs. The overarching challenge is the very low boiling point of h2: it boils around 20.

The use of hydrogen as a decarbonized fuel and for long-term energy storage involves various types of hydrogen-based solutions. These solutions must be capable of delivering clean power via hydrogen fuel for the production, transport, storage, and use of hydrogen, with lower overall emissions than alternative decarbonized energy-storage technologies. Thermochemical technologies, including hydrogen as energy storage, provide the only long durations required for seasonal and daily fluctuations in renewables. The hydrogen value chain hydrogen is used in a power-to-gas (p2g) approach as energy storage for excess renewable power that can be stored at high pressures and transported via pressurized pipelines, typically up to 1,440 psi.

The growth of renewable energy resources increases the need for energy storage. Excessive energy could be stored into hydrogen, but its transportation in pipelines requires compression up to pressures of 70 bar and high volume flows. Due to several benefits, centrifugal compressors could be considered for hydrogen transportation. Previous investigations indicate that the achievement of the required pressure rise needs high tip speeds, resulting in high mechanical stresses. This paper proposes forward-swept impeller blades to reduce the tip speed. 1d methods are used to design compressors with different outlet blade angles. The performance of three compressors is analyzed numerically.