Reciprocating piston compressors [ edit ]

by Admin

Posted on 13-05-2024 01:30 PM

Hydrogen is typically produced at relatively low pressures (20–30 bar) and must be compressed prior to transport. Most compressors used today for gaseous hydrogen compression are either positive displacement compressors or centrifugal compressors. Positive displacement compressors can be reciprocating or rotary. Reciprocating compressors use a motor with a linear drive to move a piston or a diaphragm back and forth. This motion compresses the hydrogen by reducing the volume it occupies. Reciprocating compressors, sometimes called recips for short, are the most commonly used compressor for applications that require a very high compression ratio. 1rotary compressors compress through the rotation of

gears, lobes, screws, vanes, or rollers.

There are six different type of hydrogen compressors that are widely used in the hydrogen economy. Reciprocating compressors: in a reciprocating hydrogen compressor, a piston or plunger compresses the hydrogen gas. As the piston or plunger moves back and forth, it increases the pressure of the hydrogen gas by reducing its volume. A reciprocating hydrogen compressor is typically used for low- to medium-pressure applications and are known for their high efficiency and durability. Centrifugal compressors: in a centrifugal hydrogen compressor, a spinning impeller compresses the hydrogen gas. As the impeller spins, it generates a high-velocity flow of hydrogen gas, which is then converted into pressure by a diffuser.

In a cylinder, the piston moves down, and the inlet valve opens and lets gas fill in the cylinder. When the piston moves back up, the volume reduces, increasing the pressure of the gas. Reciprocating compressors of fer one of the most mature technologies with the ability to generate high discharge pressure. The size and capacity can be tailor-made as per the requirements. The reference image is of a two-stage reciprocating compressor. Where the first stage’s output acts as an input for the second stage. One of the key challenges with these compressors is a lot of moving parts leading to breakdown and regular maintenance, heat management, possible contamination of hydrogen gas with oil, vibrations and noise, and metal embrittlement.

Ionic liquid piston compressor [ edit ]

Mechanical compressors are the most widely used compressors to compress low-pressure hydrogen into high-pressure tanks by using mechanical energy in which with the lowering of

confined volume, gaseous hydrogen can be squeezed into smaller chambers and result in higher gas pressures. In the following sections, general mechanical compressors including reciprocating piston compressors, hydrogen diaphragm compressors and ionic liquid compressors will be briefly introduced.

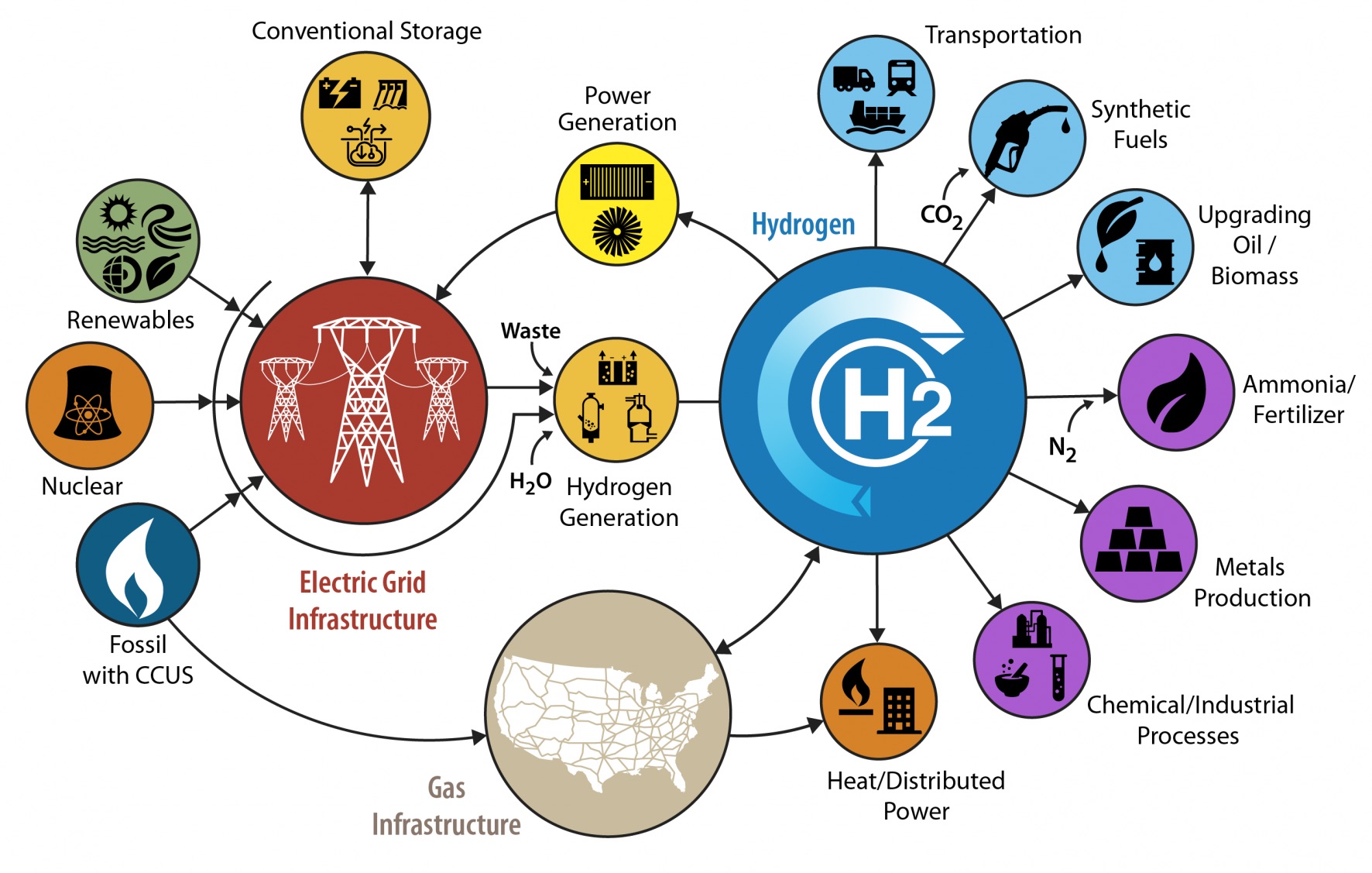

Compressors are essential to move, store or transform hydrogen. From the point at which hydrogen is produced to the point where it is consumed, our wide compression portfolio supports many applications across the hydrogen value chain. Applications for hydrogen compression include: production - gathering of green hydrogen from electrolysis, grey and blue hydrogen produced by steam methane or autothermal reformers (smrs/atrs) transportation - liquification, pipeline, storage (cavern/vessel), conversion to ammonia as h2 carrier utilization - e-fuels (ammonia/methanol), industrial applications (e. G. Green steel), mobility, petrochemical/refining feedstock, gas turbine fuel your partner for hydrogen compression solutions we are a global market leader in hydrogen compression applications with over 2500+ units operating in hydrogen applications, representing over 2,500,000 installed horsepower and over 100 years of compression experience.

Experience in system integration for hydrogen compressors the simplefuel™ team brings decades of industry experience in system integration and compression. Pdc is the # 1 supplier of hydrogen compressors for installation in hydrogen refueling stations. Our hydrogen fueling systems serve automobile/vehicle, bus, heavy and light duty trucks, and utility vehicle markets, with nearly 920 compressors installed world-wide and counting. Key features ultra high purity hydrogen compressors compression of gases without possibility of any contamination. Triple diaphragm construction isolates process gas from hydraulic oil. Therefore, the quality of gas entering and exiting from the compressor is the same. Key features diaphragm leak detection system provided for safe, rapid detection of breaches in the diaphragms and or seals.

Hydrogen is the fuel with the highest energy content per weight. Unfortunately, the density of hydrogen in atmospheric conditions is only at 90 grams per cubic meter. To achieve usable levels of energy density, efficient compression of hydrogen is essential. We have far more than 100 years of experience in hydrogen compression of fers a broad portfolio of hydrogen compressors.